Once upon a time, a long, long time ago on our home planet, we were at one with the other mammals. Our energy needs were simply for doing what all mammals do: reproduce, grow, play, hunt, gather, fight and flee. This energy was supplied entirely by what we ate and breathed, which was absolutely fine for the early hunter-gatherers.

Thermal energy

Then we discovered how to control fire and everything changed. We used it for cooking and keeping warm. We even used it as a weapon. We developed a new lifestyle in which we became dependent on thermal energy, or “heat”. Heat is generated when a combustible material or “fuel” is heated in the presence of oxygen till it catches fire and starts to burn. This is a chemical process that turns chemical energy into thermal energy. We quickly learned to meet our new energy needs by burning fuels which we found in plenty in the form of wood and other combustibles such as peat and dried animal dung.

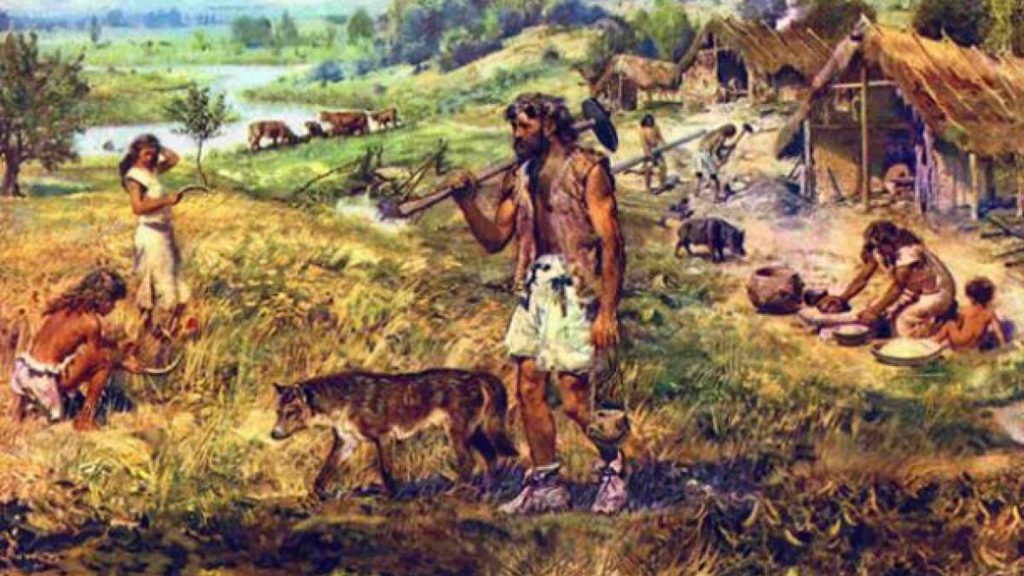

The next major milestone was to abandon the hunter-gatherer lifestyle and become an agrarian society, settling into villages and towns, farming the land and domesticating useful animals. At least most of humanity did. Once we had discovered how to mine and work iron and copper we could use fire for making metal tools and better weapons. Our dependence on chemical fuels for heat has continued to the present day.

Mechanical energy

This change of lifestyle allowed for a greater degree of cooperation and specialisation leading to great technological advances and presenting us with new challenges and new demands for energy. These were met by harnessing the mechanical energy of wind, water and animals and the thermal energy of combustible materials. In order to do this, we had to invent machines for converting energy from what was available into a form we could use and transmitting it to where it was needed.

“Necessity is the mother of invention” and so the discipline of mechanics was born: the wheel, the pulley, the cog, the rope, the axle, the lever, the chain and so on. This allowed us to harness energy from the elements, beasts of burden and humans by making machines like windmills, sails, watermills, horse mills and treadmills, and to do useful things like ploughing, pumping water, sailing boats, driving stagecoaches, operating lathes, milling machines and all manner of industrial and agricultural machinery. Mechanical energy could be transmitted tens of metres and so a single “prime mover” could power many machines at once, the founding principle of the factory. Even at this stage our energy needs were still quite modest and the amount of fuel needed to satisfy them moderate by modern standards.

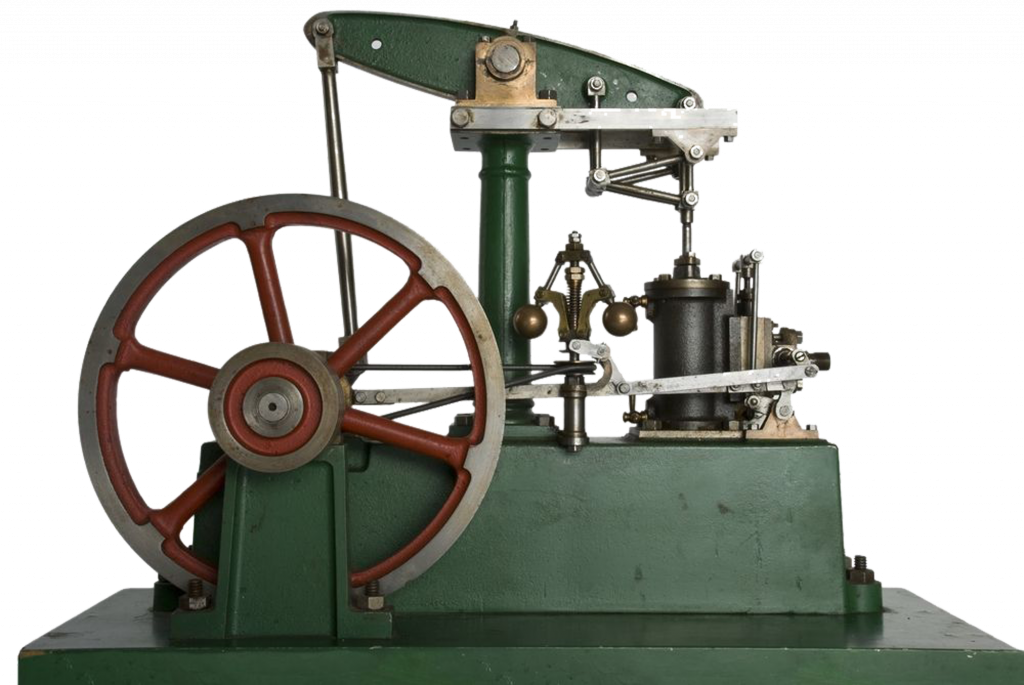

Then everything changed once again with the invention of the steam engine. This extraordinary machine was a marriage made in heaven (or hell, depending on how you look at it) between the elements of fire and water. Coupled with the discovery of coal in the ground, the steam age was born and its insatiable appetite for air and earth unleashed upon the world. There followed a positive feedback loop whereby steam engines were used in the manufacture of steam engines and the mining and processing of coal, and transporting them to wherever they were needed. Unfortunately these wonder machines produced vast amounts of carbon dioxide, airborne particulates, slag and ash. And not everyone was benefitting from this industrial revolution.

Electrical energy

After steam power the next major innovations were the controlled use of electricity and the invention of the internal combustion engine. After the basic principles of electricity were understood there followed a period of rapid development of the machines needed to generate, distribute, store and use it. Electricity generators of this era were powered by steam engines and these were powered by burning the fossil fuel coal, so this electricity was a very dirty form of energy. Consumer side machines comprised mostly motors, heaters and lighting, which between them could do practically anything we wanted (energetically speaking). The major advantage of electrical energy was that it could be transmitted hundreds, if not thousands, of kilometers with acceptable losses. This allowed power stations to be placed well away from consumers and prompted the construction of a national electricity grid. However storage devices for electrical energy were still in their infancy and had a very low energy density, making them unsuitable for most off-grid applications, including transport.

Contemporaneous with the development of electrical technology came the invention of the internal combustion engine and the discovery of extensive fossil fuel reserves of coal, oil and natural gas to fuel them. This form of energy production is far more efficient than using steam engines and, because fossil fuels have such a high energy density, was eminently suited to mobile and other off-grid applications. Not surprisingly it wasn’t long before most forms of transport were using fossil fuel powered internal combustion engines, as were manufacturing and mining which required vast amounts of thermal and mechanical energy. In a seeming volt-face [pun intended], internal combustion engines were superceded by steam turbines for driving the generators that powered the national grid. So steam was back in fashion – but with a major jump in efficiency.

Nuclear energy

Following hot on the heels of chemical energy powered machines, physics was undergoing a major revolution in the understanding of matter and energy, as quantum theory exploded onto the world and the idea of nuclear power was born. When an atom undergoes a nuclear reaction, energy is either released (exothermic) or absorbed (endothermic). Exothermic nuclear reactions can be created in such a way as to produce a chain reaction: a continuous process that turns nuclear energy into thermal energy. This process can be controlled (as in a power station) or uncontrolled (as in a bomb). There two types of nuclear reactions used for generating the energy needed for nuclear power: fission, which is the breaking up of the nucleus of an atom (and the staple of the nuclear power industry) and fusion, which is the result of nuclei combining (and is the holy grail of power generation, still some way off commercial exploitation). The energy density of nuclear fuel is orders of magnitude greater than any chemical fuel, and so is needed in much smaller quantities, but it is highly dangerous material to handle, as are many of the waste products. While nuclear power plants don’t generate any carbon dioxide, there is a significant carbon footprint and waste management effort required over the full life cycle of construction, operation, maintenance and decommissioning.

“Renewable” is a term used to describe an energy source which doesn’t involve a fuel – chemical or nuclear – and is sustainable in the sense that the supply is endless. Such sources essentially all come from the sun (either directly in the form of sunlight or indirectly in the form of weather), the moon (for tidal energy) or from the bowels of the earth (in the form of heat).

Mitigation of carbon dioxide emissions from burning fossil fuels has taken many forms and becomes more urgent with every passing year. These include carbon capture at source, carbon sequestration from the atmosphere, carbon offset projects such as tree planting, reduction of emissions in other areas, and carbon offsets trading.

Heat “mining” (such as heat pumps, geothermal and waste heat from power stations and manufacturing), storage (such as underground and phase change heat reservoirs) and distribution through local heating schemes are very small scale and can only operate over a few kilometres.

Other forms of energy production, such as green hydrogen for heating and transport, and fuel cells for generating electricity directly from hydrogen, are also still very small scale but, like fusion, will hopefully become viable in the not too distant future.

Battery technology has advanced apace as their energy density and cost compete with fossil fuels and made electric vehicles and high capacity storage a reality. However batteries are still too heavy for most airborne transport which may have to rely on green hydrogen or methane to reduce its carbon footprint for now.

Greening the Spark – one kilowatt hour at a time : –

Currently the share of global energy provided by electricity is about 10%. Unfortunately we can’t make green electricity until all the ingredients in making it are green too and this will be a gradual process taking place over many generations. The best way to see how this works is to examine what happens at various times when we construct new electricity generation facilities. What would it take to build an ideal green power station, wind/solar farm or storage facility?

First of all we need to understand what “greening” means in this context. There are three ways in which we can do damage to the planet:

- We can ruin the environment by destroying the flora and habitat for its resident fauna, thus contributing to climate change and biodiversity loss.

- We can pollute the environment by leaving toxic and other waste, with similar effects.

- We can pollute the atmosphere, rendering it dangerous to health and promoting climate change.

So “greenness” in this context is a measure of sustainability, meaning how well we succeed in NOT doing any of the above. The greenness of any method of generating or storing electrical energy can only be calculated by taking the whole life cycle into account, including that of any infrastructure required to support it. This means:

- Manufacture/construction – taking into account the greenness of all the components used and the energy required to assemble them

- Infrastructure lifecycle – taking into account the greenness of the entire lifecycle of the infrastructure for needed for operating the generator as well as for refuelling and power distribution

- Installation – the energy required to deliver and install the facilities on site

- Operation – the greenness of the generation process itself, from energy source to electricity output, including refueling and waste management

- Disposal – the greenness of the energy required to decommission and dispose of / recycle the generator in an environmentally friendly way, including any obsolete infrastructure and toxic waste and restoring the site to its former state.

At this point it will be useful to distinguish between “operation” and everything else: the non-operational overheads or just “overheads”. Also in references to fossil fuels, it will be assumed they are used without carbon capture unless explicitly stated otherwise.

As an illustration, consider building a brand new renewable energy facility such as a wind farm. Although wind is free (and green), the energy it produces will be tainted by the legacy of fossil fuel energy used for its overheads, namely construction, infrastructure, decommissioning etc. So the very first renewable energy facility will be fairly dirty overall, but cleaner than one burning fossil fuels and will help to make the National Grid just a little bit greener. A second facility is now built to make hydrogen which can be used for heating in all the processes required for creating the next renewable electricity source, say a solar farm. This facility will itself be quite dirty because both the overheads and the electricity used to make the hydrogen will be quite dirty. However, the heat produced will be greener than that produced by burning fossil fuels and will contribute to greening the other 90% of global energy production. This process will be iterated over several generations and the average greenness will get better and better each time – but it is a gradual process and takes time. The simple qualitative model shown below gives an idea of how this works, as the proportion of green energy increases over time.

Note: the numbers given here are for illustration only, referring to equivalent fossil fuel carbon dioxide emissions; the important part is the colour and the slow transition from brown to green.